Tunnel boring mahcine gantry crane, also called shield gantry crane is a special lifting equipment specially for tunnel shield construction.

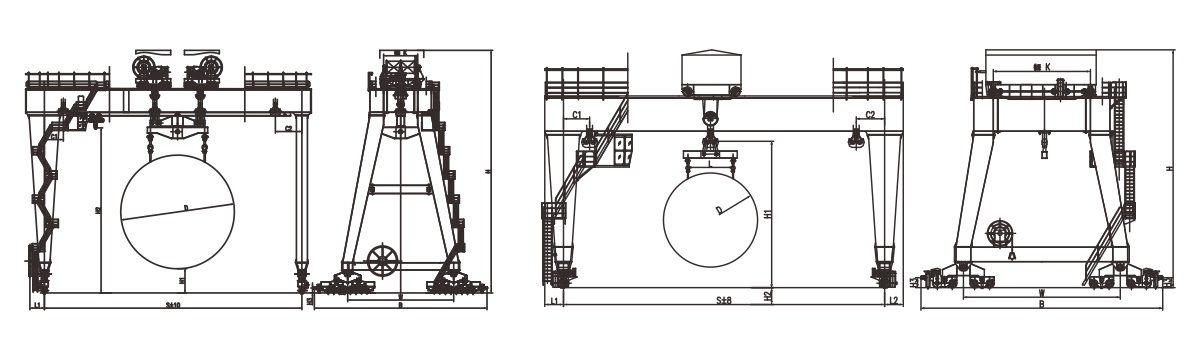

Tunnel boring mahcine gantry crane, also called shield gantry crane is a special lifting equipment specially for tunnel shield construction. And it is mainly for material lifting and pipe sheet installation in underground projects. The shield gantry crane adopts a door-type steel structure frame, which has the characteristics of high stability and strong load-bearing capacity. Its main structure consists of rigid legs, main beam and lifting trolley, which usually move along prepaved tracks. The working mechanism includes lifting, running and fine-tuning systems, which can achieve precise positioning.

The main functions of shield gantry crane include the lifting of shield machine components, the transportation and installation of pipe pieces, and the transfer of construction materials. The lifting mechanism adopts frequency conversion control, and operates smoothly and reliably. The span of the gantry can be customized according to the tunnel size, and the common range is 10-34 meters. The rated lifting capacity is generally 50-400 tons.

The advantage of shield gantry crane is that it adapts to small construction spaces and has flexible and efficient operations. Its low clearance design is particularly suitable for underground engineering environments. The control system can realize manual and semi-automatic operation, and some advanced models have remote monitoring functions. This equipment is widely applied in large-scale underground engineering projects such as subway construction and cross-river tunnels, and is an indispensable key equipment for shield construction.

Strong load-bearing capacity and precise operation control

Its advanced electrical control system supports fine-tuning operation, ensuring precise positioning and safe lifting in limited space, reducing the impact on equipment and the environment. This high-precision operation not only improves work efficiency, but also ensures safety during construction.

High adaptability and flexible mobility

The shield gantry crane has a compact and flexible design, capable of operating in narrow and complex underground environments, and adapting to tunnel spaces of different sizes and shapes. Usually installed on rails, it can move freely along the direction of the tunnel, facilitating rapid response to different operation requirements and flexible operation in a small space. The modular design makes it easy to transport, install and disassemble, especially suitable for projects with frequent site transfers.

Advanced safety protection and intelligent management system

The shield gantry crane integrates a variety of safety protection devices, such as overload protection, limit switches and emergency stop buttons. In addition, it also supports remote monitoring and fault diagnosis functions, which facilitates real-time monitoring of equipment status and timely maintenance and troubleshooting, reducing downtime and improving overall operating efficiency. These intelligent management systems significantly enhance the reliability and safety of equipment.

| Capacity | T | 100 | ||

| Span | m | 20 | 22 | 24 |

| Lifting height | m | 20 | ||

| Lifting speed | m/min | 0.37-3.7-6 | ||

| Trolley travelling speed | m/min | 0.5-25 | ||

| Crane travelling speed | m/min | 1.4-14 | ||

| Max. Wheel load | KN | 230 | 235 | 240 |

| Rail recommended | Model | QU80 | ||

| Total motor power | kw | 145 | ||

| Main dimension (mm) | Span(m) | 20 | 22 | 24 |

| Crane base distance | W | 10700 | ||

| Crane width | B | 16380 | ||

| Hook left limitation | S1 | 1750 | ||

| Hook right limitation | S2 | 1900 | ||

Professional Lifting Crane Supplier, dedicated in manufacturing overhead cranes, gantry cranes, jib cranes and electric hoists etc.

Crane Industry Zone, Changyuan City, Henan Province, China