The LH type double girder hoist bridge crane is a high performance material handling equipment in modern industrial production.

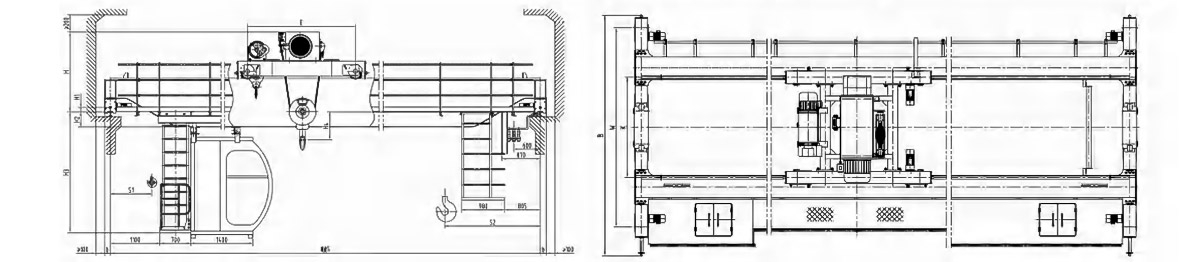

The LH type double girder hoist bridge crane is a high performance material handling equipment in modern industrial production. It features a double-girder bridge structure with a trolley mechanism that integrates electric hoists (e.g., CD, MD, or HC types) as the primary lifting component. The main beams are constructed from high-strength carbon steel, ensuring durability and load-bearing capacity. Key specifications include a lifting capacity ranging from 5 to 32 tons (depending on the model), a span of 10.5–31.5 meters, and lifting heights up to 18 meters. It supports multiple control modes: pendant, cabin, or remote operation. The double hoist bridge crane is usually for light to medium-duty working conditions (working grades A3~A4).

1. Machining Workshops: Facilitates the movement and assembly of heavy machinery parts, ensuring precision and efficiency.

2. Auxiliary Workshops in Metallurgical Plants: Supports the handling of raw materials, semi-finished products, and equipment in steel mills and foundries.

3. Warehouses: Enables efficient loading, unloading, and storage of goods, optimizing space utilization and workflow.

4. Stockyards: Handles bulk materials such as steel coils, lumber, and construction materials with ease and reliability.

5. Power Stations: Assists in the installation, maintenance, and repair of heavy equipment like turbines and generators.

6. Light Textile and Food Industries: Replaces conventional double-girder overhead cranes in production lines, offering smoother operation and adaptability for lighter loads.

Compact & Lightweight Design: Minimizes building clearance requirements while maximizing lifting height, ideal for space-constrained facilities.

High Lifting Capacity: With a lifting capacity ranging from several tons to dozens of tons, meeting the needs of different industrial operations.

Precise Operation: Advanced electrical control systems, accurate positioning of the hoist, ensuring the safety and accuracy of material handling.

High Efficiency Operation: Fasr moving hoist trolley can significantly improve the efficiency of material handling, reducing operation time and increasing productivity.

Reliable Quality: Strict quality control during the manufacturing process, excellent durability and stability, ensuring long term and reliable operation.

| Lifiting capacity | ton | 5-32 | ||||||||

| Operational method | Ground controlling; Room controlling | |||||||||

| Main hook lifting speed | m/min | 3(0.3/3) | ||||||||

| Aux. Hook lifting speed | m/min | 8(0.8/8) | ||||||||

| Cabin travelling speed | m/min | 20 | ||||||||

| Crane travelling speed | Ground | m/min | 20 | |||||||

| Room | m/min | 30 | ||||||||

| Electric hoist | m/min | HC; CD1(MD1) | ||||||||

| Lifting height | m | 9,12 | ||||||||

| Work system | m/min | A3~A4 | ||||||||

| Power supply | 3-phase A C. 380V 50Hz | |||||||||

| Steel track | P43 | |||||||||

| Span | m | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | |

| Max. Wheel pressure | Ground | kN | 96 | 103 | 109 | 115 | 120 | 125 | 131 | 135 |

| Cabin | kN | 98 | 105 | 111 | 117 | 122 | 127 | 133 | 137 | |

| Crane weight | Ground | kg | 9986 | 11876 | 14092 | 16490 | 18996 | 21500 | 24510 | 27800 |

| Cabin | kg | 11901 | 13850 | 16170 | 17720 | 21532 | 24800 | 28100 | 30950 | |

| Total Power | Cabin | kW | 35 | |||||||

| Cabin | kW | 35 | 37.8 | |||||||

Professional Lifting Crane Supplier, dedicated in manufacturing overhead cranes, gantry cranes, jib cranes and electric hoists etc.

Crane Industry Zone, Changyuan City, Henan Province, China