Single beam explosion-proof bridge crane is one lifting equipment specially for use in environments with flammable, explosive gas or dust.

Single beam explosion-proof bridge crane is one lifting equipment specially for use in environments with flammable, explosive gas or dust. Its main purpose is to ensure safety when operating in these hazardous environments and avoid the risk of explosion due to electrical equipment.

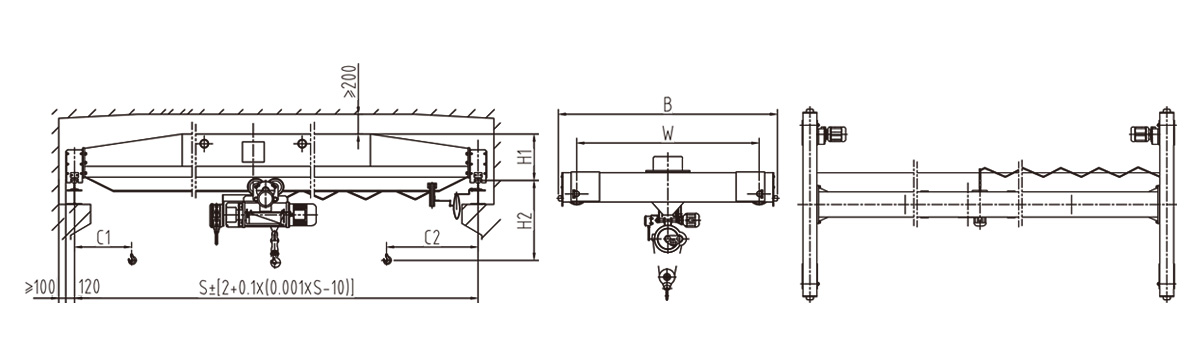

The main beam is usually made of high-strength, corrosion-resistant alloy steel or other materials that meet explosion-proof standards. In order to reduce weight while ensuring strength, the main beam often adopts a box-shaped structure design. And it is coated with a special explosion-proof coating on the surface. Taking into account the explosion-proof requirements, all electrical components inside the end beam must meet the corresponding explosion-proof grade requirements.

The electric hoist is the core part of the bridge crane, responsible for the vertical lifting of the cargo. For explosion-proof bridge cranes, the electric hoist must have explosion-proof performance.

The steel wire rope takes materials with excellent wear resistance and tensile resistance to ensure reliability during long-term use. Explosion-proof bridge crane also supports remote control and ground control. This type of bridge crane has a wide application range in many industries.

Chemical industry: When handling chemicals, it is very important to prevent fire and explosion.

Oil and gas extraction and processing: These sites usually contain large amounts of flammable gases and liquids.

Pharmaceutical industry: Certain drug production processes need to be carried out in a strictly controlled environment to prevent contamination and accidents.

High safety

Special design and materials to ensure that no sparks or high temperatures during operation.

Compact structure

Compared with traditional cranes, explosion-proof bridge crane is more compact and suitable for workplaces with limited space.

Easy operation

With an easy-to-operate control system, it can achieve precise position control and smooth lifting action.

| Lifting Capacity | 1t | 2t | 3t | 5t | 10t | 16t | 20t | ||

| Span | 7.5~22.5m | 7.5~31.5m | |||||||

| Speed | Lifting | MD1 hoist | 8/0.8 (7/0.7)m/min | 3.5/0.35m/min | |||||

| CD1 hoist | 8 (7)m/min | 3.5m/min | |||||||

| Traveling of electric hoist | 20m/min | 20m/min | |||||||

| Traveling of crane | 20/30m/min | 20/30m/min | |||||||

| Wheel diameter | Φ270 | Φ370 | |||||||

| Width of trail | 37~70mm | 37~70mm | |||||||

| Operational Model | remote control; ground handle | remote control; ground handle | |||||||

| Working Duty | A3 | ||||||||

| Power Supply | According to your demands | According to your demands | |||||||

Professional Lifting Crane Supplier, dedicated in manufacturing overhead cranes, gantry cranes, jib cranes and electric hoists etc.

Crane Industry Zone, Changyuan City, Henan Province, China