The A-type double girder gantry crane is a robust lifting solution designed for heavy-duty operations. Its A-shaped frame structure provides exceptional stability and support, making it ideal for various industrial applications.

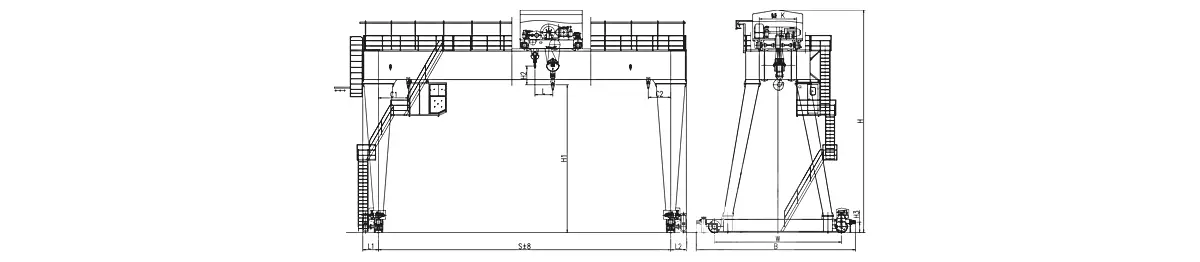

The double girder A frame gantry crane is a robust lifting solution designed for heavy-duty operations. Its A-shaped frame structure provides exceptional stability and support, making it ideal for various industrial applications. The double main beam is the core load-bearing structure of the gantry crane. It adopts a box beam design with high strength and good rigidity. This design not only increases the working space but also facilitates transportation, installation and maintenance. Its rigid outriggers are on both sides of the gantry to provide stable support. They are usually for withstanding large loads. And flexible outriggers are opposite to the rigid outriggers as flexible structures. It is to adapt to load changes and reduce structural stress. This A frame gantry crane also has a large appliacation range.

1. Outdoor Warehouses: Ideal for loading and unloading materials, enhancing operational efficiency.

2. Material Yards: Suitable for handling bulk materials, ensuring smooth workflow.

3. Railway Freight Stations: Facilitates the loading and unloading of goods, reducing operational time.

4. Port Terminals: Efficient for handling containers and bulk cargo, increasing port throughput.

5. Steel Mills: Assists in transporting and stacking steel products, maintaining production continuity.

6. Cement Plants: Aids in the handling of raw materials and finished cement, ensuring smooth production processes.

7. Mechanical Processing Workshops: Facilitates the movement and assembly of heavy machinery components, improving production efficiency.

9. Power Plants: Supports equipment installation and maintenance, ensuring reliable power supply.

10. Construction Sites: Assists in the handling and storage of construction materials, supporting construction progress.

Sturdy Structure: Box-type welded design provides strong support, ensuring equipment stability.

Diverse Power Supply Options: Available in cable drum and sliding contact line configurations to suit different working environments.

Easy Maintenance: Standardized design facilitates maintenance and reduces operational costs.

Energy Efficiency: Optimized design reduces energy consumption, improving work efficiency.

| Lifiting Capacity | Main Hook | t | 75 | 100 | ||||||||

| Aux. Hook | t | 20 | 20 | |||||||||

| Span | m | 18 | 22 | 26 | 30 | 35 | 18 | 22 | 26 | 30 | 35 | |

| Lifiting Height | Main Hook | m | 12 | 12 | ||||||||

| Aux. Hook | m | 13.1 | 13.4 | |||||||||

| Work Duty | A5 | A5 | ||||||||||

| Lifting Speed | Main Hook | m/min | 3.9 | 3.9 | ||||||||

| Lifting Speed | Aux. Hook | m/min | 7.2 | 7.8 | ||||||||

| Trolley Travelling Speed | m/min | 3.8-38 | 3.4-34 | |||||||||

| Crane Travelling Speed | m/min | 3-30 | 3-30 | |||||||||

| Power Supply | 3-phase A C. 380V 50Hz | 3-phase A C. 380V 50Hz | ||||||||||

| Crane Rail Recommended | P43 | QU70 | ||||||||||

| Max. Wheel Pressure | kN | 195 | 215 | 235 | 275 | 295 | 310 | 320 | 330 | 350 | 355 | |

| Total Power | kW | 177 | 193 | 197.6 | 212 | |||||||

Professional Lifting Crane Supplier, dedicated in manufacturing overhead cranes, gantry cranes, jib cranes and electric hoists etc.

Crane Industry Zone, Changyuan City, Henan Province, China