As a mechanical equipment for material handling, the double flap grab bucket is usually in places such as ports, docks, and mines.

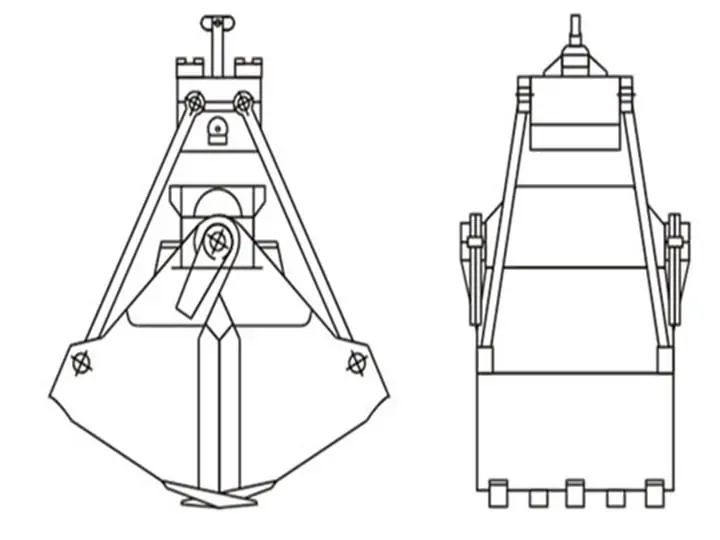

The double-flap grab bucket normally connects with bridge cranes and gantry cranes. It mainly consists of lifting wire rope, guide rope wheel, fixed pulley and upper bearing beam, movable pulley and lower bearing beam, support rod, bucket, etc.. And the two symmetrical flaps bucket are the main parts doing the open and close movement. The double-flap grab bucket lifting and lowering action is controlled by steel wire ropes. The opening and closing of the grab bucket control the retraction and extension of four steel wire ropes through an electric trolley system.

As mechanical equipment for material handling, it is usually used in places such as ports, docks, and mines. This grab bucket could perform the loading and unloading of a large amount of bulk materials. It is capable of grabbing all kinds of loose accumulations for loading, unloading, transportation, and other operations.

This type of double-flap grab bucket has mature technology. We manufacture the bushings at each hinge point with high-quality bearing steel. Also, the edge plate is quite thick, making the grab more durable and longer in its service life.

Because it can effectively adapt to materials of different shapes and sizes and has high working efficiency, it has a wide application range. We also provide customized designs to make it applicable to different crane equipment types to achieve a better and ideal lifting task.

The double flap grab bucket is widely used in various industrial environments. For example:

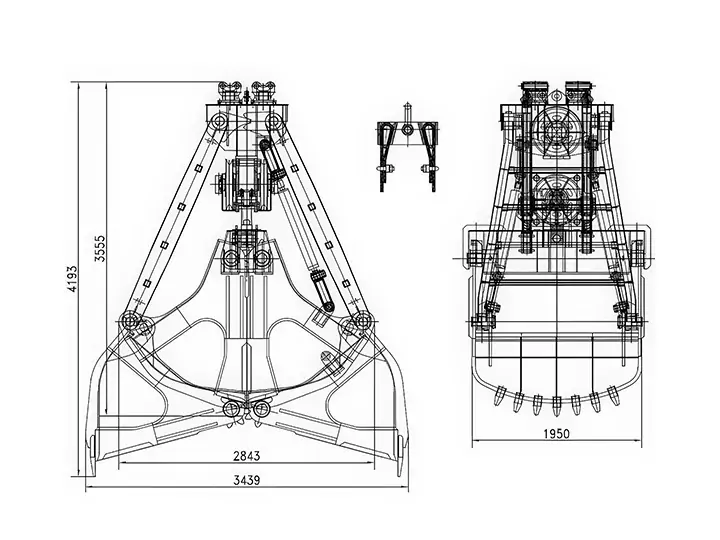

| Product Name | Double-flap Grab Bucket |

| Material | Steel |

| Rated capacity (ton) | 5-16 ton |

| Pulley diameter (mm) | 400-600 mm |

| Steel wire rope diameter (m) | 16-24 mm |

| Grab bucket weight (ton) | 2.30-7.96 ton |

| Grab bucket closing height (m) | 2.8-4.5 meter |

| Grab bucket opening height (m) | 3.1-5.3 meter |

| Grab Width (m) | 1-2.4 meter |

As a well-established manufacturer of crane equipment in China, Nucleon Crane can provide customized solutions tailored to your specific needs, including non-standard lifting capacities, lifting heights, lifting/running speeds, and adjustments to control methods. At the same time, we also provide a full range of services such as design and manufacture of lifting equipment, installation and commissioning, equipment modification, overhaul, maintenance, and annual inspection and maintenance.

If you have any specific requirements or need further assistance, please feel free to contact our team of experts. Nucleon will provide you with custom solutions and professional support.

Professional Lifting Crane Supplier, dedicated in manufacturing overhead cranes, gantry cranes, jib cranes and electric hoists etc.

Crane Industry Zone, Changyuan City, Henan Province, China