HSY Electric chain hoists have unique chain lifting mechanism and diversified functions, and are widely used in various lifting and handling tasks. There are three different types of electric chain hoist, which are suitable for different working scenarios. This article will discuss in detail the composition, differences, characteristics, application and maintenance of the three types of electric chain hoist to help readers better understand and choose this equipment.

Difference

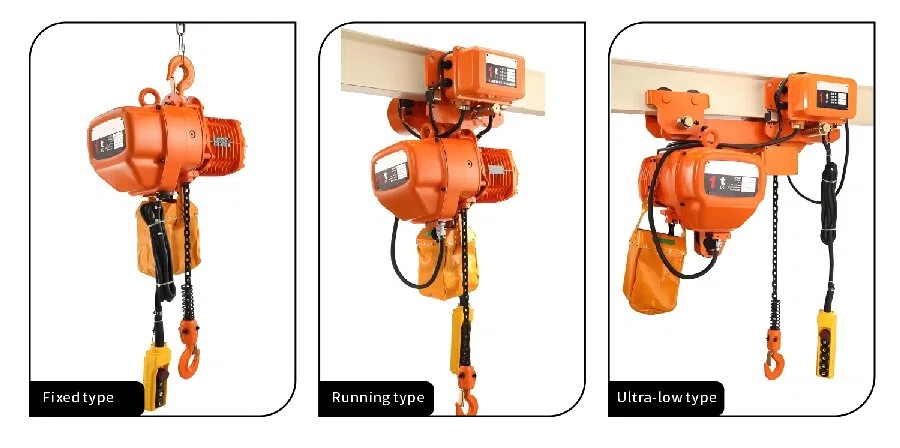

HSY electric chain hoist is mainly divided into three different types: fixed (also known as hook type), running type, and low headroom (also known as ultra-low type). All three types of electric chain hoist have the characteristics of high working level, good usability, high reliability, low failure rate and so on. The chain is not easy to fall off or jumping groove when it is running in the sprocket more stable use.

Fixed suspension type: HSY fixed electric chain hoist dose not have running mechanism, and was suspended in a fixed frame.

Running type: HSY running type electric chain hoist has running mechanism, and the monorail lower flange is the running track of the electric chain hoist.

Low headroom electric chain hoist: HSY low headroom electric chain hoist has a special structural design to reduce the distance between the body and the beam rails. It is mainly used in places where the construction of space is narrow.

Composition

Electric chain hoist is mainly composed of motor, reducer, brake, sprocket, chain and other key components. These components work together to make the electric chain hoist able to complete lifting and lowering tasks.

- motor: The motor is the power source of electric chain hoist. It is responsible for providing enough power to drive the whole equipment.

- Reducer: The reducer reduces the speed of the motor, increases the output torque, and makes the electric chain hoist smoother and more reliable during the lifting and lowering process.

- Brake: When the equipment stops working, the brake can lock the chain quickly and accurately to prevent heavy objects from falling down accidentally.

- Sprocket and Chain: The sprocket and chain are the lifting mechanism of the electric chain hoist. The sprocket and chain undertake the lifting and lowering of heavy objects. The design of the chain makes the electric chain hoist more stable in the lifting and lowering process.

Characteristics

Electric chain hoist is compact, strong and reliable. It adopts more advanced technology, fine workmanship. Here are the features of electric chain hoist

1. Small weight: Self-weight is relatively light, easy to install, according to the need to change the location of the equipment, adapted to a variety of operational occasions.

3. Dual brake system: The adoption of double braking system makes the operation of the hoist crane more flexible, the braking time is very short, and can ensure the stability of the fuselage when the equipment is subjected to emergency braking.

4. Emergency switch: The emergency switch is designed for emergency shutdown when there is some system problem.

Toepassing

Three different types of electric chain hoists are used in different work situations.

- Fixed suspension type: Fixed electric chain hoist can not move. It can only be used fixedly to lift up and down.

- Running type: The running electric chain hoist can lift up and down. It can also move left and right on the I-beam rail.

- Low headroom electric chain hoist: Low headroom electric chain hoist mainly consists of 2 running cars and a combination of electric host. It is suitable for workplaces where the height of the plant is low and where there are strict requirements on the lifting height, especially suitable for the temporary plant buildings.

Use and Maintenance

When using the electric chain hoist, users should strictly abide by the operating procedures, avoid overloading, bumping, impact. At the same time, regular maintenance of electric chain hoist is also very important.

1. Regularly clean the dust and debris on the surface of the equipment to keep it clean.

2. Regularly lubricate the key parts of the equipment to reduce wear and friction. Extend the service life of the equipment.

3. Check the electrical system: regularly check the connection and insulation of the electrical system to ensure the safe operation of the equipment.

4. Check mechanical parts: regularly check the wear and tear of mechanical parts such as sprockets and chains, and replace damaged parts in time.

As an important lifting equipment, electric chain hoist plays an irreplaceable role in the industrial field. Through the introduction of this article, readers will have an in-depth understanding of electric chain hoist and be able to find the best solution.

Verwante artikelen

- Wat is het verschil tussen een handmatige kettingtakel en een elektrische kettingtakel?

- Wat is een elektrische takel? Elektrische takel prijs en capaciteit

- Prijs portaalkraan

- Gantry Crane Structure

- Portaalkraan te koop: Het vinden van de perfecte oplossing voor uw behoeften

- Brugkraan versus portaalkraan vergelijken: hoe kiezen?