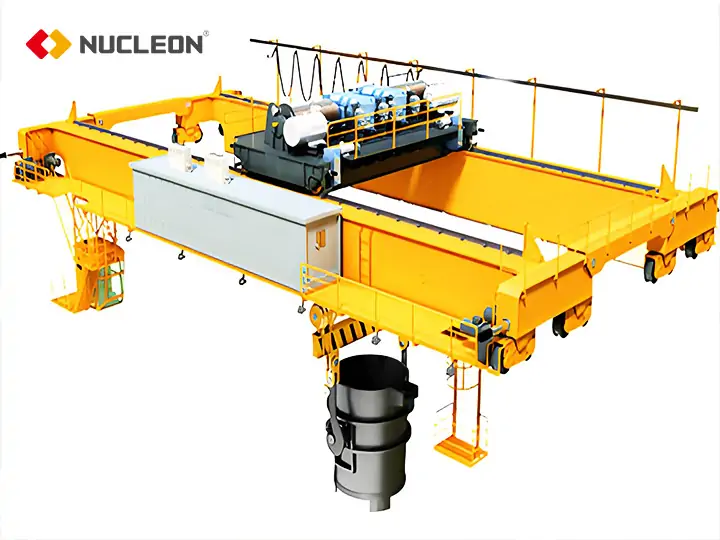

YZ type foundry casting crane is a heavy lifting equipment specially designed for steel smelting workshop, which is mainly used for lifting, transporting, pouring and blending molten iron of high temperature liquid metal and other operations.

YZ type foundry casting crane is a heavy lifting equipment specially designed for steel smelting workshop, which is mainly used for lifting, transporting, pouring and blending molten iron of high temperature liquid metal and other operations. This series of foundry cranes are mainly designed for 160/32 tons, 180/50 tons, 200/50 tons, 225/65 tons, 240/80 tons, 320/180 tons (T) and other tonnage, and the working class is A7 (heavy duty), which can satisfy the needs of harsh industrial environment.

The YZ Foundry casting crane has been comprehensively upgraded and optimized under harsh conditions such as high temperature, dust, high impact, and corrosion. It has in the metallurgical and foundry industries of an indispensable lifting equipment, ensuring safety and reliability in high-risk operations such as high-temperature molten metal.

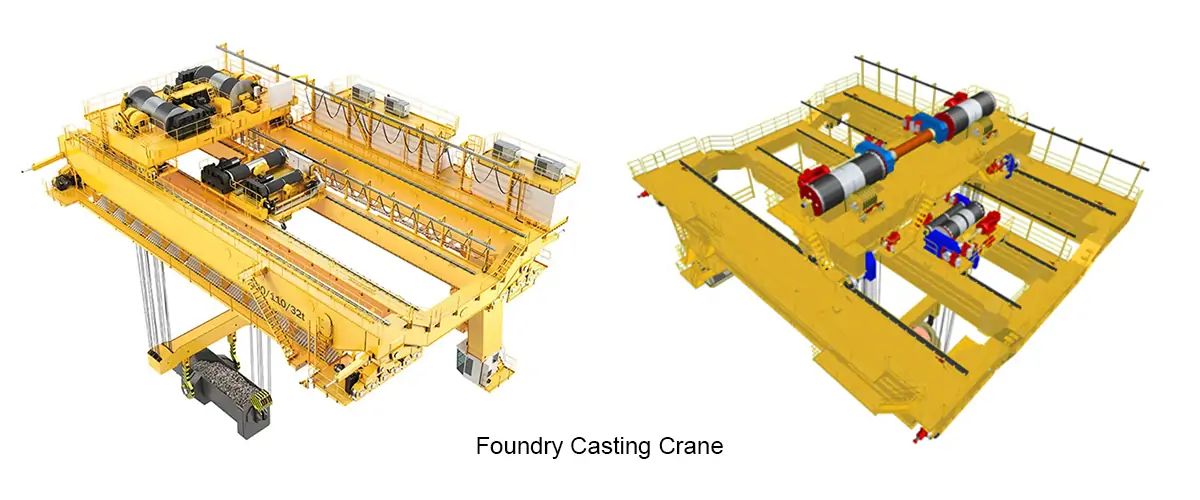

Double girder and four girder structure: Nucleon foundry casting crane is usually divided into double girder and double rail, four girder and four rail, four girder and six rail and other types. The lifting capacity of less than 125 tons usually adopts YZ type double girder structure, and the lifting capacity of more than 125 tons adopts YZS type four girder structure. YZS type four girder casting crane main structure is designed as 4 girder 6 rail.

Primary and secondary trolley design: The primary trolley is equipped with a hook beam with fixed spacing for lifting ladle. The secondary trolley is equipped with a hook that runs underneath the primary trolley to perform auxiliary operations such as steel dumping and slag cleaning in conjunction with the primary hook.

Four girders and four rails layout: The main trolley runs on the main girder track on the outside of the bridge frame, and the secondary trolley runs on the secondary girder track on the inside, realizing independent and flexible operation mode.

The YZ type foundry casting crane is composed of multiple parts, including the main beam, end beam, main trolley, Sub-trolley, electrical system, safety device, lifting mechanism, and other main parts. Below, introduce different parts, their names, and functions.

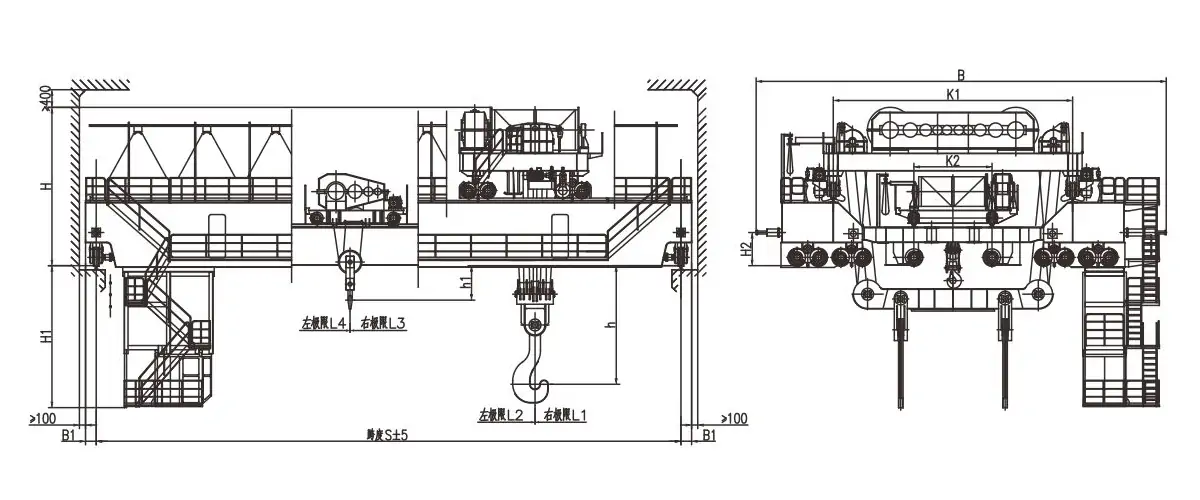

The following are the technical parameters and external dimension drawings of YZS type 180/50, 200/50, 225/65, 240/80 tons four-beam casting bridge cranes, which can be customized according to different needs.

| Lifting capacity (t) | 180/50 | 200/50 | 225/65 | 240/80 | |

| Clase trabajadora | A7 | A7 | A7 | A7 | |

| Span S (m) | 28.5 | 28 | 27 | 22 | |

| Altura de elevación (m) | Gancho principal | 27 | 26 | 32 | 25 |

| Secondary Hook | 29 | 26 | 34 | 27 | |

| Speed(m/min) | Gancho principal | 7.5 | 6 | 11 | 7 |

| Secondary Hook | 10 | 10 | 11 | 9.6 | |

| Main Trolley | 40 | 41 | 41 | 35 | |

| Side trolley | 38 | 38 | 39.5 | 38 | |

| Crane | 80 | 78 | 84 | 80 | |

| Main dimensions(mm) | H | 6850 | 6900 | 7000 | 7000 |

| H1 | 5860 | 6000 | 5990 | 565 | |

| H2 | 1350 | 1650 | 1400 | 1350 | |

| BQ | 17500 | 17000 | 17300 | 18500 | |

| B1 | 10500 | 10000 | 10100 | 11250 | |

| B2 | 3500 | 3200 | 3300 | 3800 | |

| Limit size(mm) | b | 4500 | 450 | 450 | 450 |

| H3 | 5500 | 6000 | 5800 | 5500 | |

| H4 | 1200 | 1000 | 1000 | 1500 | |

| S1 | 2450 | 2600 | 2500 | 2800 | |

| S2 | 3000 | 3000 | 3000 | 3200 | |

| S3 | 2000 | 2000 | 2200 | 2400 | |

| S4 | 1600 | 1600 | 1600 | 2800 | |

| Maximum wheel pressure (KN) | 525 | 530 | 550 | 545 | |

| Recommended rails | QU120 | QU120 | QU120 | QU120 | |

| Alimentación | Three-phase AC 380V-50Hz | ||||

Nucleon Crane, as a professional manufacturer of foundry casting cranes, has 20 years of R&D and manufacturing experience. We provide highly customized solutions including: lifting capacity, lifting height, lifting/running speed, control mode and other parameters. We also provide the following full range of services:

Contact us now for more details or a quote on Foundry Casting Crane!

Proveedor profesional de grúas de elevación, dedicado a la fabricación de puentes grúa, grúas de pórtico, grúas pluma y polipastos eléctricos, etc.

Zona industrial de grúas, ciudad de Changyuan, provincia de Henan, China