Project Background

The client is a medium-sized Bangladeshi shipyard that builds and repairs offshore cargo ships and tugboats, has seen an increase in orders in recent years, and the traditional manual lifting methods with old lifting equipment have not been able to keep up with production demands. As a result, the company requested an inquiry about Nucleon's column jib cranes.

Requirements Identification

During the initial approach, Ratan mentioned that “the lifting capacity of the column jib crane should not be less than 4 tons and it should ensure easy and quick operation, high safety and must be able to withstand salt spray corrosion during the monsoon season in Bangladesh”.

Hani, Nucleon's sales manager, quickly coordinated a team meeting with the technical development, engineering, and after-sales support departments. Through a remote video system, our technical team systematically analyzed the operating environment, load conditions, and corrosion factors of the Chittagong shipyard.

Solution:

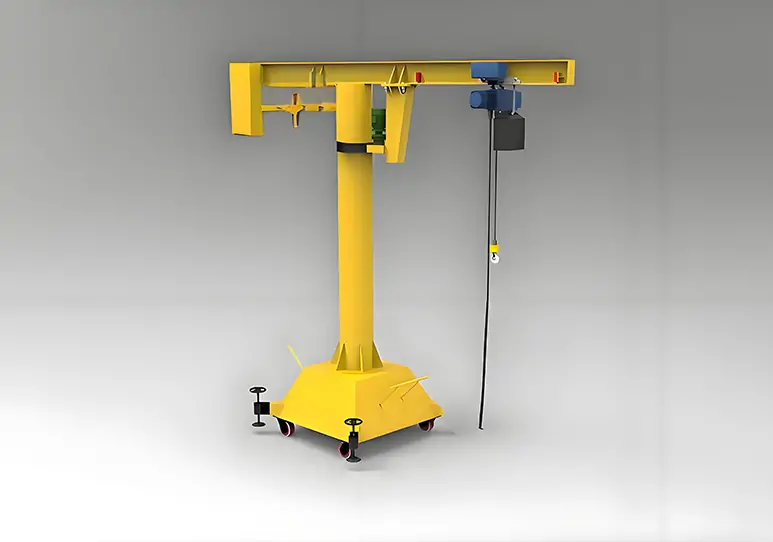

Based on the requirements, we recommended a 5-ton column jib crane and completed the customized solution design within a week. This 5-ton column jib crane features high load capacity, an easy operation system, an adjustable jib design, and corrosion-resistant materials. The following are specific specifications:

- Arm Length: Up to 10m

- Load Capacity: 0.25–5t

- Rotating Angle: 180°, 270°, 360°

- Power Supply: 220–690V, 50/60Hz, 3-phase

- Control Method: Pendant control and remote control

Implementation Process:

- Site Survey: The technical team conducted an on-site assessment to determine the optimal installation location and technical parameters.

- Customized Design & Production: The engineering team developed tailored designs based on survey results.

- Quality Inspection: Each unit underwent testing before shipment.

Testing & Certification: The 5 ton column jib crane was tested in compliance with international standards, including load tests and safety evaluations. Then the 5 ton column jib crane was shipped after obtaining the necessary certifications.

Shipping & Delivery: We planned a transportation strategy. After weeks of sea freight, the 5 ton column jib crane arrived at the Bangladeshi port.

Installation & Commissioning: Our technical team provided on-site installation and commissioning to ensure operation. Then we conducted operator training for the customer’s staff.

Customer Feedback:

The 5 ton column jib crane has improved the shipyard’s productivity and efficiency. The customer praised the equipment’s stability and reliability, as well as our professional service.

Conclusion:

This successful export of the column jib crane to Bangladesh showed our capability in customized solutions, technical expertise, professional service, and efficient logistics. The customer Ratan expressed his trust and willingness to cooperate with Nucleon in the future.