Definition eines Brückenkrans

Ein Brückenkran ist eine Art von Hebevorrichtung, die häufig über Werkstätten, Lagern und Materiallagern eingesetzt wird und hauptsächlich zum Heben von Materialien dient. Sein strukturelles Merkmal ist, dass er sich über den Arbeitsbereich spannt, wobei beide Enden auf Betonsäulen oder Stahlkonstruktionsträgern aufgebaut sind, und seine Gesamtform ähnelt einer Brücke, weshalb er auch allgemein als "Brückenkran" oder "Laufkran" bekannt ist. In diesem Artikel erklären wir Ihnen, was ein Brückenkran ist? Definitionen, Komponenten, Typen, Anwendungen, Kosten und vieles mehr helfen Ihnen, eine bessere Wahl der Brückenkranlösungen zu treffen.

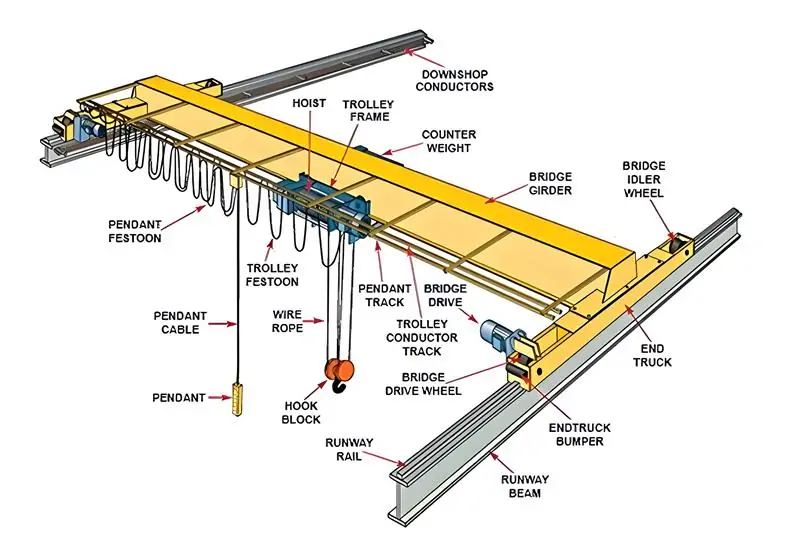

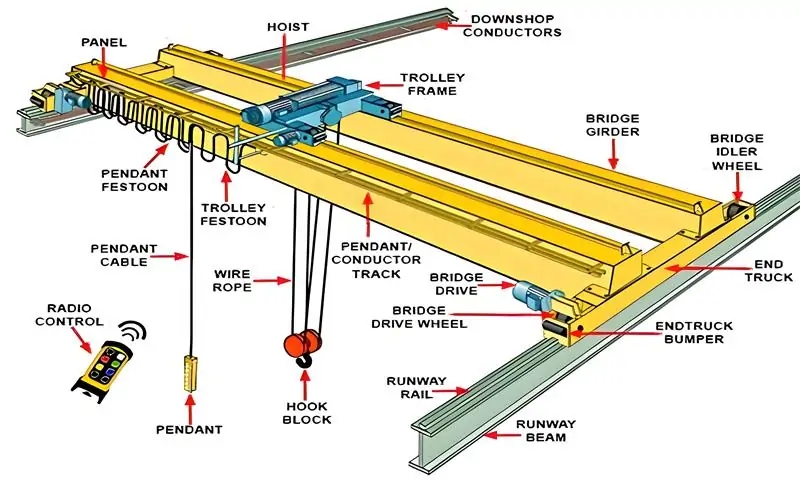

Aus welchen Teilen besteht ein Brückenkran?

Die Komponenten von Brückenkränen variieren je nach ihrer Bauweise und werden hauptsächlich in zwei Typen unterteilt: Einträgerkräne und Zweiträgerkräne. Unabhängig davon, ob es sich um einen Einträgerkran oder einen Zweiträgerkran handelt, gehören zu den Hauptkomponenten Hakensatz, Drahtseil, Rollensatz, Reduzierstück, Bremse und elektrisches Steuersystem. Im Folgenden werden die strukturellen Merkmale und die Beschreibung der Hauptkomponenten aufgeführt:

Komponenten von Einträger-Brückenkränen

Die Struktur der Einträger-Brückenkräne ist relativ einfach und besteht hauptsächlich aus einem Hauptträger, einem Endträger, einem elektrischen Hebezeug und einem Laufwerk. Der Hauptträger ist in der Regel ein Kasten- oder I-Träger, und der Elektrozug läuft entlang des unteren Flansches des Hauptträgers, um das Heben und horizontale Bewegen von Materialien zu ermöglichen. Der Laufmechanismus umfasst große und kleine Laufkatzen, die für die Längs- bzw. Querbewegung zuständig sind. Einträgerkräne sind für leichte und mittlere Lasten geeignet und zeichnen sich durch eine geringe Stellfläche und niedrige Kosten aus.

Komponenten von Zweiträger-Brückenkränen

Zweiträger-Brückenkräne besteht aus zwei parallelen Hauptträgern, Endträgern, Hubwerk und Katzfahrwerk. Die Hauptträger sind durch Querträger miteinander verbunden und bilden eine stabile Rahmenkonstruktion. Das Hubwerk ist in der Regel auf der Laufkatze montiert, die entlang des oberen Flansches des Hauptträgers läuft und größere Tonnagen tragen kann. Zweiträgerkräne eignen sich für das Heben von schwerem Material und haben den Vorteil einer hohen Stabilität und einer großen Tragfähigkeit.

wie funktioniert ein Brückenkran?

Der Brückenkran führt die Hebevorgänge hauptsächlich durch die Zusammenarbeit von Elektrozug und Laufkatze aus. Das folgende ist sein Arbeitsprinzip und Betriebsmechanismus:

- Antrieb eines elektrischen Hebezeugs

Die elektrische Hebevorrichtung ist das Herzstück des Brückenkrans und besteht hauptsächlich aus Motor, Getriebe, Trommel und Drahtseil (oder Kette). Der Motor wandelt die Hochgeschwindigkeitsrotation über das Getriebe in eine Niedriggeschwindigkeitsleistung mit hohem Drehmoment um, treibt die Trommel an und treibt so das Drahtseil oder die Kette an, um das Heben und Senken des Hakens zu erreichen, und kann auch die Höhe des angehobenen Objekts über das Steuerungssystem genau einstellen. - Horizontale Bewegung des Elektrofahrwerks

Die elektrische Laufkatze ist ein Schlüsselelement für die horizontale Bewegung von Brückenkränen und wird in der Regel an der Hauptträgerschiene installiert. Die Laufkatze wird von einem unabhängigen Motor angetrieben und läuft über ein Getriebe oder einen Riemenantrieb entlang der Schiene. Der Bediener kann die Bewegungsgeschwindigkeit und -richtung der Laufkatze über das Steuersystem einstellen, um das angehobene Objekt genau an den Zielort zu transportieren. - Doppelträger von Brücke und Gleis

Die Brücke des Brückenkrans besteht in der Regel aus einer Ein-Träger- oder Zwei-Träger-Konstruktion, wobei die beiden Enden der Brücke durch Endträger auf der Schiene abgestützt sind. Das Schienensystem ist zweigleisig ausgelegt, so dass der Kran bei Längsbewegungen stabil und ausgeglichen ist.

Brückenkran-Typen

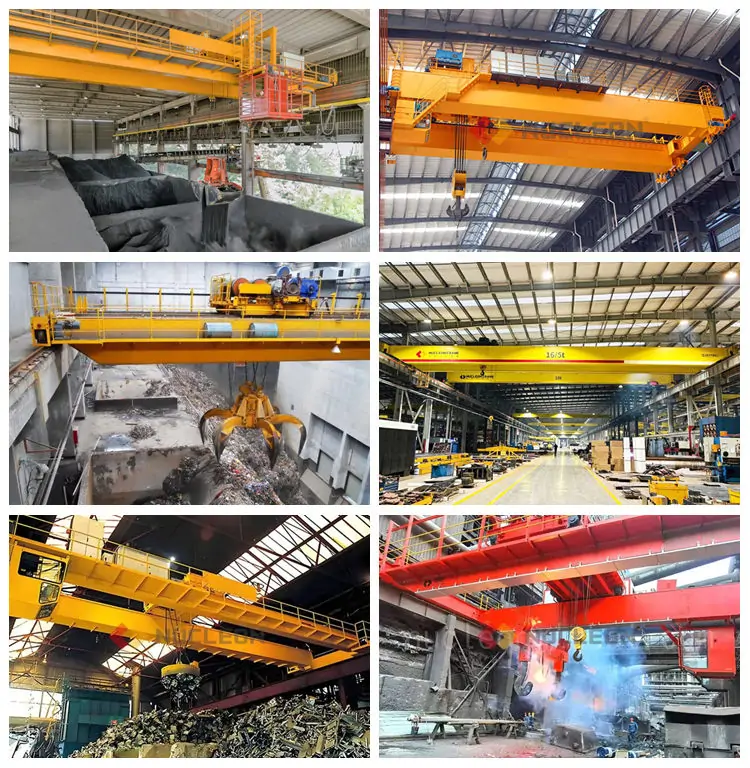

Es gibt viele Arten von Brückenkränen, die den unterschiedlichsten Anforderungen gerecht werden, vom einfachen Materialtransport bis hin zu speziellen Industrieanwendungen, die wie folgt unterteilt werden können:

Einteilung der Streuerarten

- Hakenkran: nimmt Standardhaken als Spreizer, weit verbreitet in allen Arten von Materialtransport-Szenarien, mit starker Vielseitigkeit und einfache Bedienung.

- Greiferkräne: speziell entwickelt mit einer Greifvorrichtung, die sich zum Greifen von Schüttgut wie Kohle, Erz usw. eignet, um die Effizienz beim Be- und Entladen zu verbessern.

- Elektromagnetischer Kolbenkran: Nutzt das elektromagnetische Prinzip zur Aufnahme von Metallobjekten, geeignet für die Handhabung von Metallmaterial in Stahlwerken usw., mit präziser Steuerung und berührungslosem Heben.

Differenzierung der Anwendungsbereiche

Brückenkräne für allgemeine Zwecke

- Anwendbar auf eine Vielzahl von Betriebsumgebungen, umfassende Funktionen, ist eine gemeinsame Hebezeuge in Fabriken und Lagern.

Spezialisierter Brückenkran

Konzipiert für spezifische Anforderungen der Industrie, einschließlich, aber nicht beschränkt auf:

- Schmiede-Laufkran: konzipiert für Schmiedewerkstätten, die hohen Temperaturen und Stoßbelastungen standhalten können.

- Metallurgische Brückenkräne: geeignet für die raue Umgebung in der metallurgischen Industrie, mit hoher Temperatur- und Verschleißfestigkeit.

- Brückenkräne für Kraftwerke: die für die Wartung von Kraftwerken eingesetzt werden und in der Lage sind, schwere Stromerzeugungsanlagen zu heben.

- Explosionsgeschützter Brückenkran: geeignet für brennbare und explosive Bereiche, um die Betriebssicherheit zu gewährleisten.

- Isolierter Brückenkran: zur Verwendung in elektrischen Arbeitsbereichen, um die Stromleitung zu verhindern.

- Hochbelastbarer Brückenkran: Hebekapazität von 50 t bis 500 t, entwickelt für das Heben von schweren Gütern, mit großer Hebekapazität.

Klassifizierung der Hauptträgerstruktur

- Kastenförmiger Laufkran: der Hauptträger hat eine geschlossene Kastenstruktur, hohe Festigkeit, gute Stabilität, geeignet für Schwerlastbetrieb.

- Fachwerk-Brückenkran: Der Hauptträger ist als Fachwerk konstruiert, wodurch das Gewicht reduziert und eine ausreichende Festigkeit beibehalten wird, und eignet sich für Gelegenheiten mit großer Spannweite.

- Rohrleitungsbau Brückenkran: Rohre werden innerhalb des Hauptträgers zur Übertragung des Mediums oder als strukturelle Unterstützung angeordnet, was meist bei speziellen Prozessanforderungen der Fall ist.

- Trägerkräne: Einfache Profilträger aus Stahlprofilen (z.B. I-Trägern) und Stahlplatten werden mit Elektrozügen als Hebezeug eingesetzt, was wirtschaftlich und praktisch ist und sich für leichte bis mittlere Lasten eignet.

Wofür wird ein Brückenkran verwendet?

- Automobil und Transport: Brückenkräne transportieren Materialien an Montagelinien in der Automobilindustrie, um die Effizienz zu steigern, und in der Transportindustrie helfen sie vor allem beim Entladen von Schiffen und bei der Beschleunigung des Transports von großen Gütern.

- Luft- und Raumfahrt: Brückenkräne werden vor allem in der Luft- und Raumfahrtindustrie in Hangars eingesetzt, um schwere Maschinen präzise und sicher zu bewegen, und eignen sich für die Handhabung teurer Gegenstände.

- Betonherstellung: Effizientes und sicheres Bewegen von Fertigteilen und vorgeformten Teilen, die häufig in Hallen in Fabriken verwendet werden, während Reifenportalkräne häufig auf Außenhöfen eingesetzt werden.

- Metallbearbeitung: für den Umschlag von Rohstoffen, das Schmelzen von Fässern und das Verladen von Fertigprodukten können Anbaugeräte für den Transport verschiedener Metallprodukte hinzugefügt werden.

- Kraftwerk: hauptsächlich in Wärme- und Wasserkraftwerken, Windkraftanlagen und bei der innerbetrieblichen Materialförderung eingesetzt.

Wie hoch sind die Kosten für einen Brückenkran?

In der nachstehenden Tabelle haben wir Preisspannen für Brückenkräne verschiedener Tonnagen angegeben. Diese Preise dienen nur als Referenz. Der genaue Preis des Brückenkrans hängt von Ihren detaillierten Anpassungsanforderungen zum Zeitpunkt des Kaufs ab.

| Tragfähigkeit | Spannweite | Preisspanne |

|---|---|---|

| 10-20 Tonnen | 10-20m | $39,000 - 78,000 |

| 20-50 Tonnen | 10-30m | $78,000 - 198,000 |

| 50-100 Tonnen | 10-30m | $198,000 - 480,000 |

| 100-500 Tonnen | 10-30m | $480,000 - $1,200,000+ |

Wichtige Faktoren, die den Preis beeinflussen

- Spannweite und Hubhöhe: Neben der Tonnage sind auch die Spannweite und die Hubhöhe des Krans wichtige Faktoren für die Preisgestaltung. Größere Spannweiten und größere Hubhöhen erfordern oft komplexere Strukturen und stärkere Materialien, was die Herstellungskosten erhöht.

- Arbeitsumgebung und besondere Anforderungen: Wenn der Brückenkran in extremen oder besonderen Umgebungen (z. B. hohe Temperatur, niedrige Temperatur, Feuchtigkeit, korrosive Umgebungen, etc.) arbeiten muss, kann es aus speziellen Materialien und Beschichtungen hergestellt werden, um die Anforderungen der Anti-Korrosions-, Anti-Explosions-, Anti-magnetische und so weiter zu erfüllen.

- Konfiguration und zusätzliche Merkmale: Unterschiedliche Konfigurationen und zusätzliche Merkmale wirken sich ebenfalls erheblich auf den Preis aus. So sind Brückenkräne mit Fernsteuerung, variabler Frequenzregelung, Energierückgewinnung und anderen Funktionen sowie mit fortschrittlichen Sicherheitsvorrichtungen ausgestattet, in der Regel teurer.

- Grad der kundenspezifischen Anpassung: Wenn Sie einen stark individualisierten Brückenkran benötigen, z. B. spezielle Gleispläne, nicht standardisierte Größen oder Spezialspreizer, sind zusätzliche Konstruktions- und Herstellungskosten erforderlich, so dass der Preis entsprechend höher ist.

Um sicherzustellen, dass Sie die Brückenkranlösung erhalten, die Ihren Anforderungen am besten entspricht, wenden Sie sich bitte an Kontaktieren Sie uns und wir werden Ihnen eine optimierte, maßgeschneiderte Lösung anbieten, die auf Ihren spezifischen Anforderungen an die Arbeitsbedingungen und Ihr Budget basiert.

Brückenkran Gebrauchs- und Instandhaltungsvorkehrungen

Einsatz und Wartungsmaßnahmen für die wichtigsten Komponenten von Brückenkränen:

- Hakengruppe: Da es sich um ein Gerät handelt, das Materialien direkt befördert, muss die Oberfläche des Hakens glatt sein, und Risse oder andere Beschädigungen sind streng verboten, um die Sicherheit des Hebevorgangs zu gewährleisten.

- Riemenscheibengruppe: einschließlich der dynamischen Riemenscheibengruppe und der festen Riemenscheibengruppe, deren Oberfläche keine Risse aufweisen darf, und die Riemenscheibe muss gewährleistet sein, dass sie sich bei der Arbeit flexibel drehen kann. Wenn die Riemenscheibe beschädigt ist, darf sie nicht durch Schweißen repariert werden, sondern muss rechtzeitig ersetzt werden.

- Stahldrahtseil: Es sollte regelmäßig überprüft werden, um sicherzustellen, dass keine gebrochenen Drähte, gebrochenen Litzen, Knoten, Rost oder Pockennarben vorhanden sind.

- Rollengruppe: Es ist das Kernstück der Drahtseilaufwicklung im Hebemechanismus, und seine Oberfläche sollte glatt sein, um Abnutzung und Rillenbildung des Drahtseils während des Betriebs zu vermeiden.

- Untersetzer: Er wird verwendet, um die hohe Geschwindigkeit des Motors auf die erforderliche Geschwindigkeit zu reduzieren. Er sollte gleichmäßig und ohne Sprünge, Stöße oder abnormale Geräusche laufen, wobei zu prüfen ist, ob die Befestigungselemente locker sind.

- Kopplung: Dient der Verbindung zweier koaxialer oder paralleler Wellen zur Übertragung von Drehmoment und zum Ausgleich von Winkel- und Radialversatz. Der Zustand der Verbindung sollte regelmäßig überprüft werden, um sicherzustellen, dass keine Lockerheit oder Abnutzung vorliegt.

- Bremsen: In der Regel auf Hochgeschwindigkeitswellen installiert, um das Bremsmoment zu reduzieren. Es ist darauf zu achten, dass die Bremsbeläge keine Brandspuren oder Gerüche aufweisen und dass die Reibfläche des Bremsrads nicht mit Öl verunreinigt ist.

- Radgruppe: durch Räder und Winkelstahl-Lagergehäuse montiert. Wenn die Felge weniger als 10 mm abgenutzt ist, muss sie gemeldet und genau beobachtet und gegebenenfalls ersetzt werden.

- Puffer: Die Elastizität des Materials, das dazu dient, die beim Aufprall des Krans oder der Laufkatze auf die Prallplatte entstehende Energie zu absorbieren, muss regelmäßig überprüft werden, um seine Pufferwirkung zu gewährleisten.

- Widerstand: Da es sich um ein elektrisches Gerät zur Begrenzung des Motorstroms handelt, muss sichergestellt werden, dass sein Betriebszustand normal ist, um Überhitzung oder Schäden zu vermeiden.

Für weitere Informationen oder ein Angebot wenden Sie sich bitte an unser Serviceteam.