The electromagnetic overhead crane adopts the electromagnetic disc as its lifting mechanism, suitable for lifting and handling in workshops, warehouses, docks and other places.

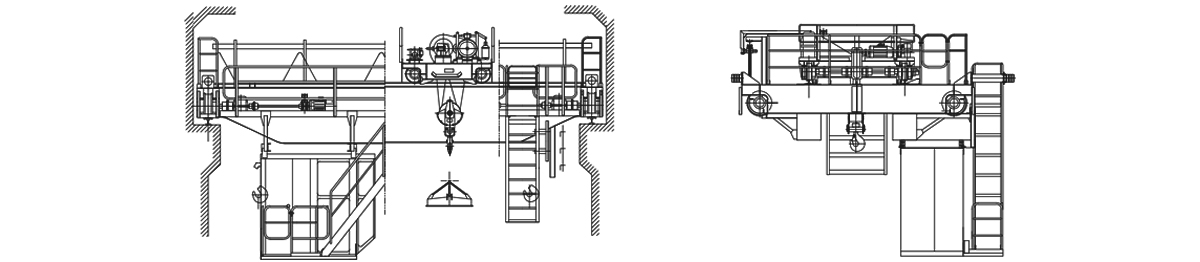

The electromagnetic overhead crane adopts the electromagnetic disc as its lifting mechanism. And its trolley running mechanism adopts the low-speed shaft centralized driving structure, and the trolley running adopts the structure of independent driving on both sides. According to the rotation, we divide mode into upper rotation type and lower rotation type. And there are three different control methods, ground operation, air operation and control operation. Users could choose the suitable control way in accordance with the actual needs.

The basic structure of the electromagnetic overhead crane is the same as that of the hook bridge crane. Main difference is that a DC lifting electromagnetic sucker is the lifting mechanism, which is for lifting the black metal and its products with magnetic conductivity. Its AC power supply is converted into DC power supply through the DC box installed in the driver's room. And then the DC power cable is sent to the electromagnetic disc through the special cable reel located on the electric trolley.

Electromagnetic bridge crane is suitable for lifting and handling in workshops, warehouses, docks and other places. Through functions of adsorption, loading and unloading, it helps achieve seamless connection of all links of item transfer and processing.

Electromagnetic overhead cranes play an important role in scrap iron recycling departments and steel-making workshops. They can easily collect and move scattered iron blocks or other iron materials without boxing, packaging or bundling.

| قدرة الرفع | 5~64 ton |

| فترة | 10.5~31.5 meter |

| ارتفاع الرفع | 5~18 متر |

| سرعة الرفع | 7.8~15م/دقيقة |

| سرعة السفر الطويلة | 87.3~116.8m/min |

| سرعة السفر المتقاطعة | 37.2~44.6m/min |

| مزود الطاقة | تيار متردد 380 فولت 50 هرتز |

| الطبقة العاملة | A5~A8 |

مورد رافعة الرفع الاحترافي، متخصص في تصنيع الرافعات العلوية، والرافعات الجسرية، والرافعات الذراعية والرافعات الكهربائية وما إلى ذلك.

منطقة صناعة الرافعات، مدينة تشانغيوان، مقاطعة خنان، الصين