Versatile Applications Across Industries

In power generation plants, overhead cranes are essential for maintenance and the handling of large components such as generators, turbines, and boilers. They provide a safe means of lifting and moving these components during installation, routine checks, and repairs, thereby ensuring continuous operation and reducing downtime.

Overhead cranes are used in maintenance shops and repair facilities where they assist in the lifting and positioning of heavy machinery parts during repair and overhaul processes. For instance, in shipyards and aircraft hangars, the bridge cranes help remove engines and other large components from vessels and aircraft for servicing.

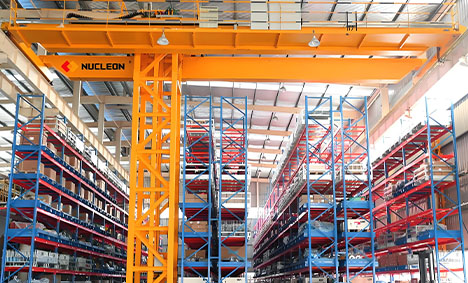

In warehousing, overhead cranes are employed for stacking and retrieving materials from high shelves, optimizing vertical storage space. They can lift pallets and crates to upper levels of the warehouse, increasing capacity without expanding the physical footprint of the facility. This application is particularly useful in densely packed storage environments where maximizing space is key.

Overhead cranes are indispensable in metal fabrication plants where they are used to move hot metal ingots, billets, and slabs. The high temperatures and weights involved require specialized cranes that are heat-resistant and durable. In steel mills, overhead cranes are crucial for handling molten metal and transporting it safely to casting areas, thus improving operational safety and efficiency.

The automotive industry relies heavily on overhead cranes for assembling large vehicle parts such as engines, chassis, and body panels. These cranes must be capable of precise movements to ensure that components are accurately positioned during assembly. They also contribute to ergonomic benefits by reducing the physical strain on workers who might otherwise handle heavy parts manually.

In manufacturing facilities, overhead cranes play a critical role in assembly line processes and general material handling. They are used to transport raw materials, components, and finished goods within the factory floor. The ability to lift and move items overhead reduces the need for floor space and minimizes interference with other operations. In addition, overhead cranes can enhance productivity by facilitating the quick transfer of materials and equipment without disrupting the workflow below.

Gantry cranes are also used in the mining industry for lifting and moving heavy equipment and materials. They are essential for handling the large and heavy machinery used in mining operations. Gantry cranes are designed to withstand the harsh conditions of the mining industry and are equipped with specialized lifting devices to handle the unique requirements of mining operations.

Shipyards often need to use gantry cranes when building ships because they require larger lifting capacity and higher lifting heights. Gantry cranes usually used in shipyards are equipped with two or more lifting hooks to adapt to different work needs.

Within railway maintenance facilities, gantry cranes serve an essential function in the repair and maintenance of locomotives and rolling stock. They are capable of lifting entire railcars or individual components, such as engines or wheel sets, for repair or replacement. This application not only enhances productivity but also ensures worker safety by minimizing manual handling of heavy objects.

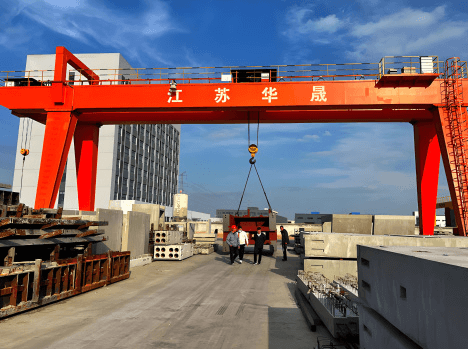

On construction sites, gantry cranes provide a portable and flexible lifting solution, especially useful in urban areas where space constraints limit the use of larger equipment. They can be assembled and disassembled quickly, making them easy to relocate as needed throughout the construction process. Gantry cranes are particularly valuable during the erection of prefabricated structures or when lifting materials to upper floors of buildings under construction, ensuring safe and controlled movement of heavy loads.