It is suitable for lifting and carrying objects in outdoor cargo yards, warehouses, harbors, construction sites and places not suitable for installing overhead cranes.

Double Girder Gantry Crane is a mature product which has been promoted in our company for many years, with the advantages of durability, safety, reliability and wide application, etc. It is suitable for lifting and handling of objects in outdoor freight.

It is an essential lifting equipment for lifting and carrying objects in outdoor cargo yards, warehouses, harbors, and construction sites. With its two main girders, the MG gantry crane provides greater load-bearing capacity to safely carry heavier loads or large components.

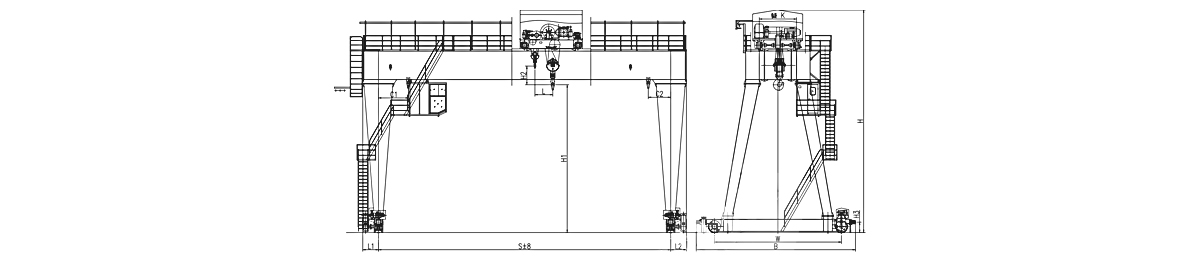

The lifting and opening mechanism of gantry crane adopts the classic parallel axis arrangement. Trolley running mechanism is with the low-speed shaft centralized driving structure. Its trolley has a structure of independent driving on both sides. And the wheel set has a variety of structures according to the different crane wheel pressure. Due to the movable trolley system, it could travel back and forth on the main beam to provide precise positioning control. And at the same time, the entire gantry can also move along the track, further expanding the operating range.

The MG type gantry crane is a reliable and efficient solution for outdoor material handling needs. Its robust design, advanced features, and customized options make it a top choice. With a focus on safety, durability, and comfort, the MG gantry crane could deliver outstanding performance in a variety of industrial settings.

| Lifting capacity | Main | ton | 5—800 |

| Auxiliary | 5—80 | ||

| Span | meter | 18—36 | |

| Lifting Height | 10—22.5 | ||

| Duty | A5 | ||

| Speed | Main | m/min | 0.1~1 |

| Auxiliary | 7 | ||

| Crab travelling | 0.5~5 | ||

| Crane travelling | 1~10 | ||

| Max.Wheel Loading | kw | 650 | |

| Total Power | kw | 330 | |

| Crane Rail Recommended | QU120 | ||

| Power Supply | 3-Phase A.C.50Hz 380V | ||

Professional Lifting Crane Supplier, dedicated in manufacturing overhead cranes, gantry cranes, jib cranes and electric hoists etc.

Crane Industry Zone, Changyuan City, Henan Province, China